DESCON Infrastructures Pvt. Ltd. is an engineering organisation shaping the face of highway & urban infrastructure ecosystem.

As an Infrastructure Development Company, DESCON designs and constructs products as well as services showcasing modern and innovative technology to deliver safe and sustainable roads. In the 25th year of it’s operation, we are proud to present ourselves as an engineering organization catering to various infrastructural demands to construct long life roads.

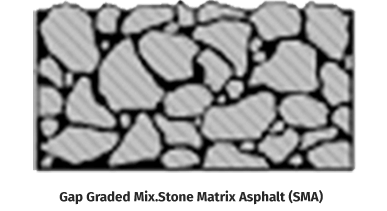

To achieve sustainable pavements, DESCON has partnered with J. Rettemaier & Sohne, Germany (JRS) & offers bitumen coated cellulose fibers. Such bitumen coated cellulose fibers help to achieve a better exo-skeleton structure in the aggregates, more popularly known as Stone Matrix Asphalt (SMA).

Descon is committed to the task of bringing sustainability to the Indian Asphalt/ Pavement Industry. With JRS, as it’s technological partner, Descon is committed to delivering research, high-quality, functional organic fibers made from renewable, plant-based raw materials. With the innovative JRS organic fiber technology, the many functions of these valuable natural substances available to industry.

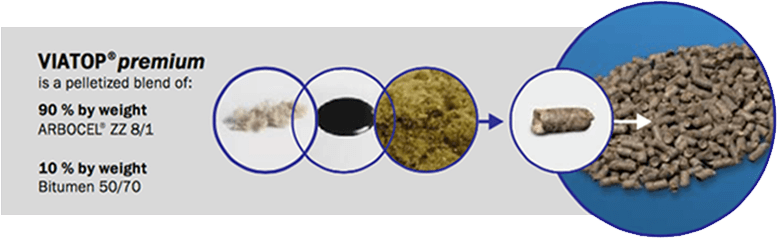

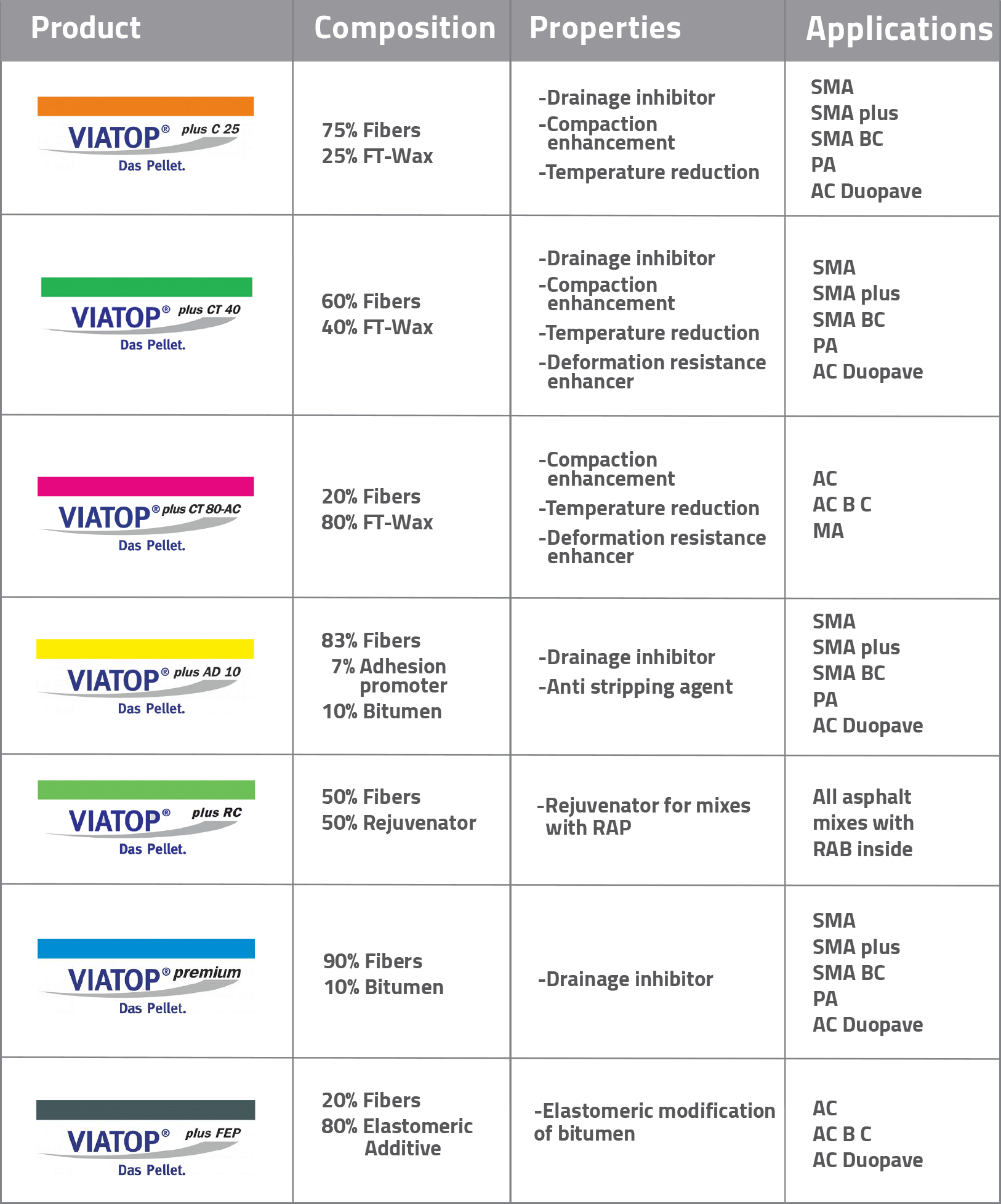

J. Rettenmaier & Söhne, Germany, is the earliest promoter of the Stone Matrix Asphalt (SMA) technology in Germany. JRS is a dedicated group who have directed their efforts in the development and processing of high - quality, organic fibres derived from natural and sustainable raw materials. Their R&D expertise, application know - how and innovations have earned them unparalleled reputation in the asphalt industry. JRS’s flagship product VIATOP pellets - fibres with bituminous coating and functional additives are the benchmark for fibre additives delivering high quality and functionality for modern asphalt concepts.

VIATOP® Premium is the highest quality of bitumen coated cellulose fiber which have been developed with the aim of achieving consistent & highly stable asphalt surface. Natural fibers made from specially treated cellulose qualities which are combined with bitumen to ensure a quick and uniform dispersion in the mix.

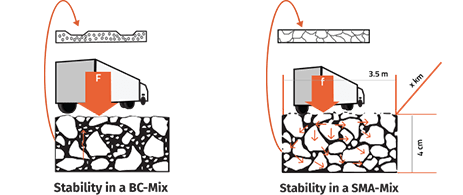

High stability to permanent deformation and higher wear resistance by an excellent particle interlock and a high content of crushed premium aggregates.

Longevity and durability to premature cracking and ravelling by a very high content of bitumen and a void less mastic mortar which fills the voids of the stone skeleton and binds it together: Good quality of bitumen is prerequisite for a long useful service life.

Stabilizing additives assurances the homogeneity (no binder drainage) of the mix during the manufacturing, transportation and laying. As a side effect, they improve the stability.

The stability in a SMA- Mix is obtained through the Internal friction in the self supporting stone skeleton

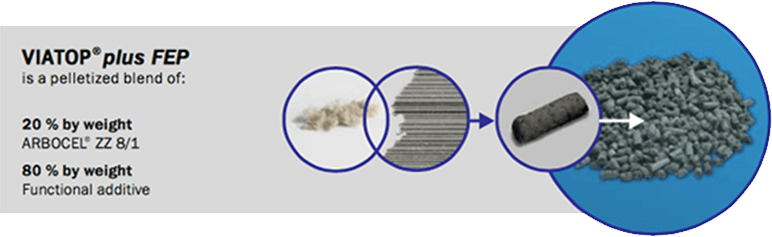

VIATOP® Plus FEP represents the new generation of elastomer modifier for standard asphalt mixtures as a cost - efficient & environmental friendly solution. In VIATOP® Plus FEP, the cellulose fiber is pelletized using Functional Elastomeric Polymer (thus the name FEP), with a cross linker. Here cellulose fibers are used, for carrying the polymer in the hot mix plant.

With exposure to increased traffic volume, higher axle load & drastic climatic changes, bituminous courses suffer from increased fatigue & rutting. In order to achieve improved performance, polymer sciences have been introduced to the asphalt industry. Polymer Modification ensures increased resistance against higher traffic volumes, improved adhesion and cohesion & higher performance in colder temperatures.

In addition to this, a non - homogenous supply of high grade bitumen PmB 40 and the constant fluctuation in prices is a major barrier in the development of good quality bitumen courses. With VIATOP® Plus FEP, pavement construction can be carried out at economical costs by combining bitumen of grade VG 30 with VIATOP® Plus FEP, thereby attaining similar results as PmB 40.

- Limited availability of polymers

- Stability in price

- High flexibility and long storage life

- Compatible with all standard road construction bitumen types

- Sustainable product by saving natural resources

- Reduction of greenhouse gas emissions

- No additional costs for the modification process

- No health and safety problems at handling and dosing

- Modification without reaction time (dry process)

- Economical product - cost savings possible

NOTE: VIATOP® Plus FEP, when dosed in the hot mix, this modifies the BC mix or in other words, this modifies the VG30 bitumen grade to the level of PmB40. An addition of 12.5% of Viatop Plus FEP, of the bitumen content, will modify the bitumen with softening temperature of 70°c. (A 10% will modify to 60°C & 15% will modify to 80°C. A 5% addition, will modify VG30 to the level of VG40).

Ahmedabad

Gujrat

Maharashtra

Bengaluru

get your quote or call: +91-98381-06614

We are here to answer you. Please fill the form and our team will contact you.